|

|

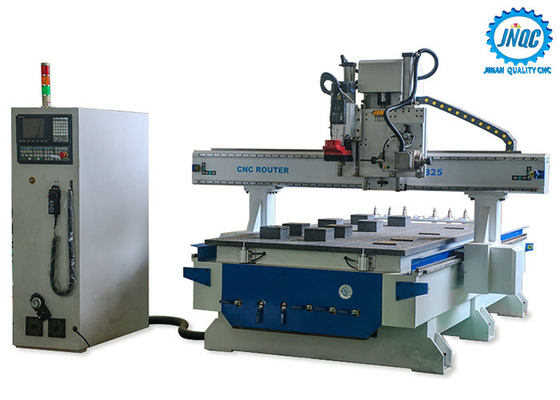

ATC Cnc Router Machine For Woodworking Door Lock Holes Drilling

|

Product Details:

Payment & Shipping Terms:

|

| Name: | Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325 | Control System: | SYNTEC 6MA Control System |

|---|---|---|---|

| Working Area(mm): | 1300 X2500 X 250mm | Motor & Driver: | Yaskawa Digital Servo Drivers And Motors 750W |

| Rail: | Hiwin NO.30 Square Linear Rails And Blocks | X, Y Structure: | Rack And Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure: | Hiwin Rail Linear Bearings And TBI Ball Screw | Software Compatibility: | Type3, Ucancam, Artcam, Wentai, JDPaint, Mastercam, Powermill, Alphacam |

| High Light: | ATC Cnc Router Machine,Lock Holes Cnc Router Machine |

||

Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325

Descriptions of Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325:

Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325 has 2 spindles, which can change automatically when processing according to your toolpath file, the right spindle is designed with 2 cutters and installed horizontally, so this spindle can only work horizontally for side milling, slotting and drilling for keyholings or processing different engraving effects on doors, windows, cabinets, tables, chairs, plates, kitch furnitures and others.

The left spindle adopts ATC 9.0KW HQD automatic tool changer spindle, which changes different cutters automatically in short time (6 seconds) for different processing effects on 2D/3D machining of woodworking, cabinet making, door making, mold making, wood arts, wood crafts.

1. Welded structure by thick profiled steel stabilized under high temperature, ensures minimum distortion, excellent rigidity and powerful strength.

2. High quality Hiwin ball bearing, wide linear lead rail and self-lubricating guiding blocks for the machine. It can balance the force in all directions to ensure the machine’s accuracy and strength when machining.

3. Z axis can be heightened to 350 mm, so it is suitable for processing large-scale and super-thick material.

4. The design of intelligent processing cross-border protection can prevent the excessive process caused by mechanical impact.

5. The diversified processing speed can be controlled separately. The speeds of idle and working setting improve the quality of processed products and processing efficiency greatly.

6. Extra heavy duty welded steel frame and gantry for maximum straightness and rigidity.

7. 9.0KW ATC HQD air cooled spindle with stable and time-saving tool-changer..

8. 8 position linear ATC with precision tool clamping.

9. Yaskawa digital servo drivers and motors for high power, accuracy and speed.

10. SYNTEC 6MA interfaced Numerical Control System with MPG XYZ AC Hand Wheel for easy origin and work piece setting.

11. Auto-Tool setting device.

12. Inverter: Taiwanese Delta Inverter control.

13. German Schneider Electronic Spare Parts.

14. Japanese OMRON approximity limits.

15. Shanghai ECHU cable with double sheathed, fire retardant and highly flexible towline cable can be bent 300,000 times.

![]()

![]()

Applications of Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325:

Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325 can process not only 2D flat projects such as : carve ,engrave , mill and cut characters, letters, pattern, and 3D relief and embossment but also 4 axis products from the following materials:

1. Almost all nonmetals: all kinds of woods, solid wood, plywood, MDF, bamboo, MDF, acrylic, PVC, organic glass, PCB, plastic , foam and others.

2. Hard nonmetals (needs water-cooling) : natural marble, granite, bluestone, sandstone, artificial stone, tombstone, headstone , quartz stone ,milestone, memorial stone, ceramic tile, ceramics, jade or jade stone, crystal, glass,Man-made marble and others.

3. Soft metals (needs cutting fluid-cooling) : copper, brass, aluminum , or aluinium composite panels, aluminum plate, aluminum sheet and aluminum parts .

Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325 CNC router machine is widely used in many fields :

1. Furniture / Woodworking industry: Chair, door, table, window, bed, cabinet, showcases, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs,art murals, headboards, redwood classical and antique furniture, exquisite European furniture, flat panel-type furniture processing, decorative products sculpture, Wave Plate, man-made marble cabinet table surface or other carving.

The horizontal spindle with 2 cutters can easily do side milling, slotting and drilling on keyholings or processing different engraving effects on doors, windows, cabinets, tables, chairs, plates, kitch furnitures and others.

2. Advertising Industry: advertising identification, Billboard, signage, badges, logo, company plate, signs, emblem, display panels, fair signs, building numbers, signs of decoration, literal hole cutting etc.; 3D character cutting, acrylic cutting, LED/neon channel, lightbox.

3. Artwork Industry: Solid wood ornaments, souvenirs, gifts, instrument 3D surface engraving, musical instruments, photo frame, Wood crafts, gift box, jewelry box and other exquisite art crafts.

4. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

5. Mold Industry: artificial marble, plastic sheeting, PVC, wood, wooden planks ,foam and soft metal molds such as copper mould , aluminum mould for building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould, sculpture ,car body making, boat and building model, ship model, pattern making.

ATC spindle engraving:

![]()

ATC spindle cutting:

![]()

Horizontal spindle slotting (right side-engraving):

![]()

Horizontal spindle slotting (left side-engraving):

![]()

Application sampes:

![]()

Technical Parameters of Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325:

| Item: QCR1325 | ATC cnc router 1325 with horizontal spindle | ||||

|

Equipment size (length*width*height) |

3200*2220*2280*mm |

||||

| Working size(X*Y*Z) mm |

1300 x 2500 x 250mm (4* 8 ft) |

||||

| Spindles | Brand | Chinese HQD ATC spindle + HQD Horizontal spindle | |||

| Rate & sets | 9.0kw + 4.5kw | ||||

| Cooling mode | Air-circulating cooling | ||||

| Rotating speed | 0-18000rpm/Min | ||||

| Frequency inverter | Taiwan DELTA 11.0kw | ||||

| Motor & Drive system | Motor |

Japanese YASKAWA SERVO motor 750W* 4 sets (for X,Y Z axis); |

|||

| Drive |

Japanese servopack 200V SGD7S-5R5A00A002 * 4 sets (for X, Y, Z axis); |

||||

| Motor reducers | Japanese SHIMP reducers | ||||

| Operating system | SYNTEC 6MA control system with handwheel | ||||

| Structure | Table structure | Extra heavy- duty frame with aggravated bed ( tempering treatment) | |||

| Rail | Hiwin NO.30 square rails | ||||

| X transmission |

Germany WMH Herion 1.5 M high precision helical gear |

||||

| Y transmission |

Germany WMH Herion 1.5 M high precision helical gear |

||||

| Z transmission | Taiwan TBI ball screw | ||||

| Working table | Vacuum and T-slot Combined | ||||

| Vacuum adsorption system | 11.0kw water-cooling vacuum pump | ||||

| Dust collector / cleaner | 5.5kw with 2 collecting bags | ||||

| Tool changer | 8 position linear autimatic tool changer ATC with precision tool clamping | ||||

| Lubrication system | Auto centralized lubrication | ||||

| Wire & cable |

Shanghai ECHU cable with high-flexibility and shielding function |

||||

| Wiring standard | CE Wiring standard | ||||

| Electric appliance | German Schneider Electronic Parts.

Japanese OMRON approximity limits. |

||||

|

Max Speed

|

Idle | X axis | 50000mm/Min (60 alarm) | ||

| Y axis | 50000mm/Min (60 alarm) | ||||

| Z axis | 6000mm/Min | ||||

| Working | X axis | 40000mm/Min | |||

| Y axis | 40000mm/Min | ||||

| Z axis | 5000mm/Min | ||||

| Precision | Process | ±0.02mm | |||

| Reposition | ±0.05mm | ||||

| Command code | G code | ||||

| Software compatibility | Type3, Artcam, Castmate, Ucancam, JDpaint, WENTAI,Mastercam, Powermill and others | ||||

| Working voltage | AC 380V, 50HZ | ||||

| Running environment temperature | 0 - 45 Centigrade | ||||

| Relative humidity | 30% - 75% | ||||

|

Weight net / gross |

1800KG / 2200KG |

||||

Machine Parts of Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325:

Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325 in factory:

![]()

HQD 9.0KW ATC spindle and 4.5KW spindle on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

![]()

![]()

SYNTEC 6MA with handwheel on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Controlling carbinet on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Taiwan Delta inverter for controlling spindle on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Japanese YASKAWA servopack 200V driver SGD7S-5R5A00A002 for YASKAWA servo motor 750w on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

8 position linear autimatic tool changer ATC with precision tool clamping on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Hiwin rail & helical rack transmission with brush on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Hard-limit protector on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Cylinder-positioners (X:2 ; Y:3 ) on Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325:

![]()

Our Similar router machines with Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325:

Linear ATC router machine with 8 tools

![]()

Linear ATC router machine with swing function

![]()

Disc ATC CNC Router

![]()

![]()

![]()

![]()

ATC CNC Router with Double Disc Tools Magazine

![]()

Disc ATC CNC Router with followed disk

![]()

![]()

2 spindles + drilling head CNC Router with auto uploading and offloading devices

![]()

Our Service of Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery 1325:

1. Installation and Debugging:

Customers can get detailed operation manual and instruction video of our CNC stone router. We will make sure that customers can operate machines skillfully.

2. Training: Customers can get free technical training. Mainly training are as follow:

1). Software operation.

2). Machine operation and maintenance.

3). Instruction of technical parameters, as well as their setting ranges.

4). Solutions for common problems.

5). Training -free in our factory.

3. Equipment Maintenance:

1). Life-time free technical consultant and software updating service.

2). Life-time customer Service responding in 24 hours.

4. Guarantee:

The guarantee period shall be 36 months counting from the date on which the machine arrives destination port. Except the damage artificially, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. After the guarantee of 36-month quality period, the parts required to repair or change, if any, we offer the cost price (agent price ) with the parts.

5. Standard Package List as below:

1). Standard plywood case, its compressive strength and bearing quality is better.

2). The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3). When importing, the plywood case is with fumigation-free, the procedure is simple.

|

Wood Door Lock Holes Drilling ATC Cnc Router Woodworking Machinery QCR1325 |

1 set |

| Tool cutters / kits |

20 pics |

| Collets | 6 sets |

| Clamps | 12 sets |

| Dust collector /clearner 5.5kw with 2 collecting bags and hose | 1 set |

| Proximity Limit for spare | 4 sets |

| Tool box | 1 set (with spanners,U disk for controlling software parameters, working samples and so on) |

About us:

Q1: How about warranty?

A1:

1. The guarantee period shall be 24 months counting from the date on which the machine arrives destination port. Except the damage artificially, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. After the guarantee of 24-month quality period, the parts required to repair or change, if any, we offer the cost price (agent price ) with the parts.

3. Afterservice person in charge : Skype / whatsapp/ Wechat/ Tel: +8613176441785

Q2: What's the delivery time?

A2: 10-15 working days to delivery.

Q3: What's the usually delivery terms?

A3: FOB, CIF, DDP, Ex works will be OK.

Q4: What's the MOQ?

A4: 1 set.

Q5: What's the delivery port?

A5: Usually Qingdao port, also we can deliver machines to Shanghai port and Guangzhou.

Q6: What's the packing?

A6: Iron Pallet and export- standard Plywood cases .

Q7: Can you place OEM orders?

A7: Yes,OEM orders are acceptable. We can manufacture machines according to your requirement with your design,logo,color,materials or brand information.

Q8:Where is your factory located? How can I visit there?

A8:Our factory is located in JiNan City, Shandong Province, China, about 2 hours from Beijing, 3.5 hours from Shanghai and 10 hours from Guangzhou by high-speed train.

Contact Person: Miss. Carol Zhu

Tel: 0086 131 7644 1785

-

Easy Operate CNC Router Machine , Computerized Wood Carving Machine 1530

-

Durable Mini 6090 Wood Router Machine For Small Business Cnc Engraving Machine

-

4 Spindles Simple ATC Portable Cnc Router Woodworking Machine 4x8

-

4th Rotary Axis Hobby CNC Router Machine For Aluminum Wood MDF 6090

-

4 Spindles Simple ATC Cnc Wood Router For Woodworking Machine 4x8ft

-

Mini Portable Hobby Diy Cnc Router Wood Carving With High Performance