|

|

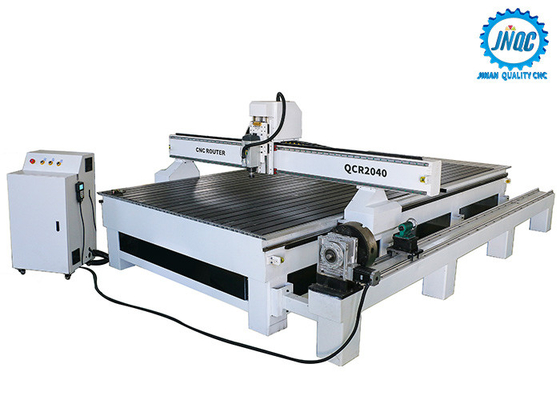

4th Rotary Axis Wood Chair Legs CNC Router Lathe Machine

|

Product Details:

Payment & Shipping Terms:

|

| Name: | 2020 Best CNC Router Lathe Machine With 4th Rotary Axis Wood Legs Chair Legs | Control System: | RichAuto A18 DSP (4 Axis) |

|---|---|---|---|

| Working Area(mm): | 2000*4000*180mm | Motor & Driver: | YASKAWA 750W Servo Motor And Drive *4 Sets |

| Rail: | Taiwan Hiwin NO.20 Square Linear Rails And Blocks | X, Y Structure: | Rack And Pinion Drive, Hiwin Rail Linear Bearings |

| Working Table: | T-slot Working Table | Software Compatibility: | Type3, Ucancam, Artcam, Wentai, JD Paint, Mastercam ,Powermill |

| High Light: | 2040 cnc router engraving machine,2040 cnc router cutting machine |

||

2020 Best CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs

Descriptions of 2020 Best CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs

1. The CNC wood carving machine adopts Italy 3.5KW HSD air-cooled spindle and the drive system adopts Japan servo motor 750w and servo drive, which guarantee the high speed and positional accuracy of the motor when working. .

2. RichAuto A18 DSP control system does not need to connect to PC, which is easy to operate and learn, especially for the beginner.

3. Intelligent processing cross-border protection is to prevent the mechanical impact phenomenon caused by the excessive design layout then processing format.

4. The CNC wood carving machine can do three-dimensional processing with fast, smoothly carving/cutting, and it can be realized off-line operation.

5. Using the higher precision Rack and pinion transmission for X and Y axis, ball screw transmission for Z-axis, ensuring the machine fast speed and higher precision.

6. The CNC wood carving machine adopts 4th axis rotary device, which can process cylinder materials, such as wood legs, chair legs. The rotary diameter and length can be optional.

7. Auto oil lubrication to make the maintenance more easy.

8. Emergency stop button, ensuring the operation safe.

9. Good software compatibility : uitable for Type3, Artcam, Castmate, Ucancam, JDpaint, WENTAI and others.

Applications of 2020 Best CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs

1. Plate processing: Insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

2. Wood products: Voice box, game cabinets, computer tables, sewing machines table,instruments.

3. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

4. Furniture: Wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

5. Cylindrical objects (with rotary device): 360° carving human body, buddha ,statues, sculptures, handicrafts, furniture decorations , wood handicrafts, wood stair, handrail armrest and stone column.

Technical Parameters of 2020 Best CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs

| Item: QCR2040 |

CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs |

|||

| Working size(X*Y*Z) mm |

2000*4000*180 mm with rotary diameter : |

|||

| Spindle | Brand | Italy HSD brand | ||

| Power & sets | 3.5kw | |||

| Cooling mode | air-cooling | |||

| Speed | 0-18000rpm/Min | |||

| Motor & Drive System | Mode | servo | ||

|

Motor |

Japanese YASKAWA servo motor 750w | |||

| Drive | Japanese servo driver SGD7S-5R5A00A002 | |||

| Amount | 4 sets (dual motors for Y axis) | |||

| Frequency inverter | Brand | FULING | ||

| Power & sets | 3.7kw | |||

| Operating system | RichAuto A18 DSP (4 axis) | |||

| Structure | Table structure | Heavy duty aggravated bed (tempering treatment) with thickness 6mm | ||

| Rail | Taiwan Hiwin NO.20 | |||

| X transmission | 1.25M high precision helical gear | |||

| Y transmission | 1.25M high precision helical gear | |||

| Z transmission | Taiwan TBI ball screw | |||

| Working table | T-slot working table | |||

| Automatic centralized lubrication | ||||

| Reducer | Japanese SHIMP reducer | |||

| Dust cleaner / collector | 3.0KW with 2 collecting bags | |||

| Wire | Shanghai cable | |||

| Wiring standard | CE Wiring standard | |||

| Electric appliance | CHINT appliance | |||

| The electromagnetic valve | Manual | |||

| Cylinder | SDA | |||

|

Speed

|

Idle | X axis | 40-60m/Min (70 alarm) | |

| Y axis | 40-60m/Min (70 alarm) | |||

| Z axis | 6m/Min | |||

| Working | X axis | 10-35m/Min | Different speeds for different materials, tools and processes requirements | |

| Y axis | 10-35m/Min | |||

| Z axis | 6m/Min | |||

| Precision | Process | ±0.02mm | ||

| Reposition | ±0.05mm | |||

| Command code | G code | |||

| Working voltage | AC 380V/50HZ | |||

| Weight | Net weight | 1500KG | ||

| Gross weight | 1900kg | |||

| Total power | 16KW | |||

| Available tool shank diameter | Φ3.175-Φ20 | |||

Machine Details of 2020 Best CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs

Italy HSD 3.5kw air cooling spindle on CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs :

![]()

RichAuto A18 mainboard , Fuling inverter,Japanese YASKAWA servo drive *4 sets and rotary drive on CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs :

![]()

Rotary diameter 300mm,length 4000mm on CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs:

![]()

Our Service of 2020 Best CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs

1. Installation and Debugging:

Customers can get detailed operation manual and instruction video of our CNC stone router. We will make sure that customers can operate machines skillfully.

2. Training: Customers can get free technical training. Mainly training are as follow:

1). Software operation.

2). Machine operation and maintenance.

3). Instruction of technical parameters, as well as their setting ranges.

4). Solutions for common problems.

5). Training -free in our factory.

3. Equipment Maintenance:

1). Life-time free technical consultant and software updating service.

2). Life-time customer Service responding in 24 hours.

4. Guarantee:

The guarantee period shall be 36 months counting from the date on which the machine arrives destination port. Except the damage artificially, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. After the guarantee of 36-month quality period, the parts required to repair or change, if any, we offer the cost price (agent price ) with the parts.

5. Standard Package List as below:

|

CNC Router Lathe Machine with 4th Rotary Axis Wood Legs Chair Legs QCR2040 |

1 set |

| Woodworking cutters / kits |

10 pics |

| Dust cleaner / collector 3.0kw | 1 set |

| Proximity Limit for spare | 2 sets |

| Collets | 8 sets |

| Tool box | 1 set (with spanners,U disk for controlling software parameters, working samples and so on) |

About us:

Q1: How about warranty?

A1:

1. The guarantee period shall be 36 months counting from the date on which the machine arrives destination port. Except the damage artificially, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. After the guarantee of 36-month quality period, the parts required to repair or change, if any, we offer the cost price (agent price ) with the parts.

3. Afterservice person in charge : Skype / whatsapp/ Wechat/ Tel: +8613176441785 Carol zhu.

Q2: What's the delivery time?

A2: 5-8 working days to delivery port.

Q3: What's the usually delivery terms?

A3: FOB, CIF, DDP, Exworks will be OK.

Q4: What's the MOQ?

A4: 1 set.

Q5: What's the delivery port?

A5: Usually Qingdao port, also we can deliver machines to Shanghai port and Guangzhou.

Q6: What's the packing?

A6: Iron Pallet and export- standard Plywood cases .

Q7: Can you place OEM orders?

A7: Yes,OEM orders are acceptable. We can manufacture machines according to your requirement with your design,logo,color,materials or brand information.

Q8:Where is your factory located? How can I visit there?

A8:Our factory is located in JiNan City, Shandong Province, China, about 2 hours from Beijing, 3.5 hours from Shanghai and 10 hours from Guangzhou by high-speed train.

Contact Person: Miss. Carol Zhu

Tel: 0086 131 7644 1785

-

Easy Operate CNC Router Machine , Computerized Wood Carving Machine 1530

-

Durable Mini 6090 Wood Router Machine For Small Business Cnc Engraving Machine

-

4 Spindles Simple ATC Portable Cnc Router Woodworking Machine 4x8

-

4th Rotary Axis Hobby CNC Router Machine For Aluminum Wood MDF 6090

-

4 Spindles Simple ATC Cnc Wood Router For Woodworking Machine 4x8ft

-

Mini Portable Hobby Diy Cnc Router Wood Carving With High Performance